Function:

Used for Aluminum and its alloys , to adjust the Si content.Among aluminum alloy is mainly used to justify a traditional product of aluminum melt composition, it is to some metal elements with higher melting temperature, melting method and aluminium production intermediates, significantly lower melting temperature of the intermediates, which makes some metal elements with higher melting temperature at low temperatures to join to the liquid aluminum, the element content of aluminum melt to mediation.

Properties:

It has consistent content , uniform constituents , less segregation and high cleanliness

1, uniform composition, melting temperature is low

2, easily broken, easily to join

3, component content is high, easy to absorb

Character:

Waffle Ingot,also can produce as per customer require,2kgor7Kg

1, according to the melt in the required control standard and intermediate alloy element content, calculate the total mixed melt the required number of intermediate alloy content.

2, generally used to adjust the composition of the intermediate alloy joining together with the burden, and in charge middle spread evenly.

3, melt after melt processing, stir well, sample analysis.

|

name |

model |

composition% |

impurities%< |

temperature℃ |

features |

|||

|

铁Fe |

硅 Si |

铜Cu |

||||||

|

1 |

铝硼 |

AlB |

B2.5-3.5 |

0.3 |

0.2 |

0.1 |

750-800 |

toughening |

|

2 |

铝硼稀土 |

AlB3RE3 |

B2.5-3.5 RE2.5-3.5 |

0.3 |

0.2 |

0.1 |

700-750 |

toughening |

|

3 |

铝钛 |

AlTi5 AlTi10 |

Ti4.5-5.5 Ti9.5-11 |

0.3 |

0.2 |

0.1 |

950-1100 |

Easy to bending |

|

4 |

铝钛硼 |

AlTi5B |

Ti5-5.5B0.9-1.4 |

0.3 |

0.2 |

0.1 |

700-750 |

Easy to bending |

|

5 |

铝钛硼稀土 |

AlTi5BRE10 |

Ti5-6 B0.9-1.4 RE9-11 |

0.3 |

0.2 |

0.1 |

700-800 |

Easy to bending |

|

6 |

铝锆 |

AlZr5 |

Zr4.5-5.5 |

0.3 |

0.2 |

0.1 |

800-850 |

Easy to bending |

|

7 |

铝铬 |

AlCr10 |

Cr9-11 |

0.3 |

0.2 |

0.1 |

900-1000 |

Easy to bending |

|

8 |

铝镍 |

AlNi10 |

Ni9-11 |

0.3 |

0.2 |

0.1 |

750-800 |

Not brittle |

|

9 |

铝铁 |

AlFe10 |

Fe9.5-11 |

|

0.2 |

0.1 |

750-1000 |

Not brittle |

|

10 |

铝硅 |

AlSi10 |

Si9.5-11 |

0.3 |

0.2 |

0.1 |

600-720 |

Not brittle |

|

11 |

铝锰 |

AlMn10 |

Mn9.5-11 |

0.3 |

0.2 |

0.1 |

770-830 |

toughening |

|

12 |

铝镁 |

AlMg10 |

Mg9-11 |

0.3 |

0.2 |

0.1 |

600-650 |

toughening |

|

13 |

铝铜 |

AlCU50 |

CU48-52 |

0.3 |

0.2 |

|

570 |

crispy |

|

14 |

铝锑 |

AlSb4 |

Sb3.5-4.5 |

0.3 |

0.2 |

0.1 |

800-900 |

Not brittle |

|

15 |

铝锌 |

AlZn5 |

Zn4.5-6 |

0.1 |

0.05 |

0.05 |

500-600 |

Not brittle |

|

16 |

铝锶 |

AlSr10 |

Sr9.5-10.5 |

≤0.2 |

≤0.2 |

≤0.1 |

720 |

crispy |

|

17 |

铝钇 |

AlY5 |

Y4.5-5.5 |

0.2 |

0.2 |

0.1 |

720 |

|

|

18 |

铝稀土 |

AlRE10 |

RE9.5-11 |

≤0.25 |

≤0.2 |

≤0.1 |

750 |

toughening |

Perform GB8735-88 technical standard, also can according to user requirements production special content in the middle of the alloy ingot

Normally, the samples delivery is 1-3 days and the lead time for the official order is 3-15 days.

Yes, the samples will be free if you agree to place orders. Otherwise, we will charge the samples.

The United States, Canada, Europe, Africa, Asia and other countries and regions.

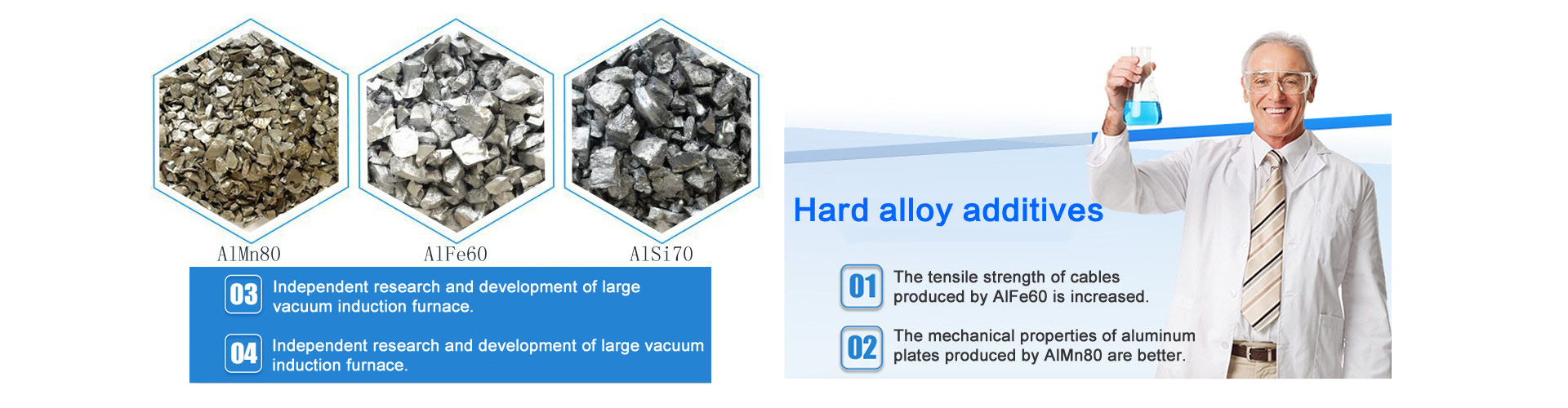

Yes, we have more than 10 years of export experience, 95% of the products exported to overseas markets. We specialize in high quality aluminum alloy Mn additive tablets, (Fe, Cu, Ti, Cr, Ni) additive tablets, quick-melt silicon and other aluminum alloy additives.