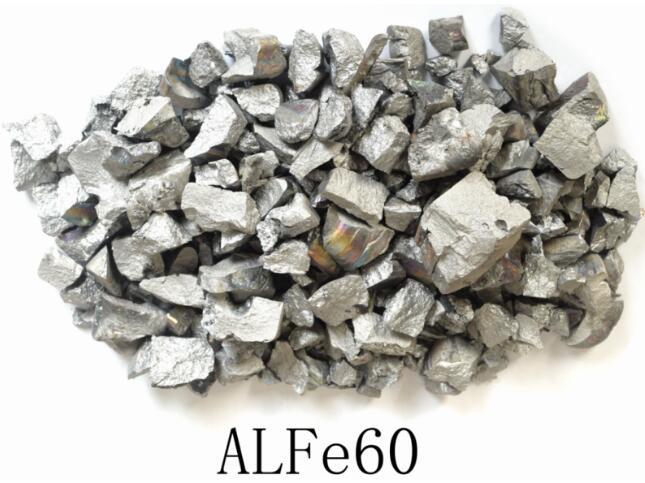

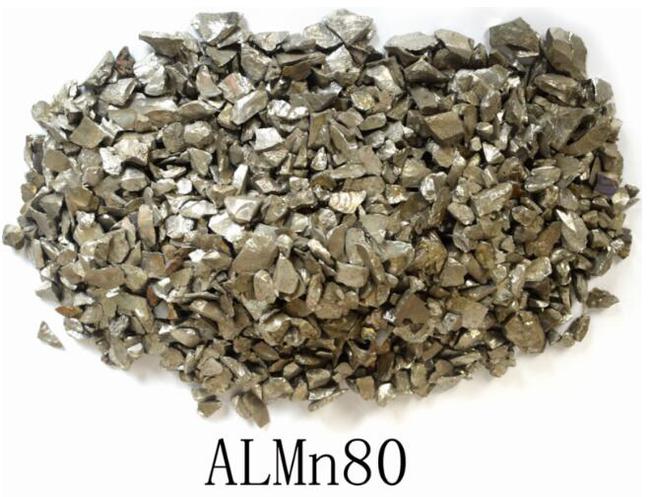

The four cemented carbide materials (AlMn80, AlCr40, AlFe60, AlSi70) that the factory has studied for 10 years participated in this international aluminum industry exhibition. It is reported that these four cemented carbide products are the first in the world, using the company's patented technology-large-scale vacuum melting technology, and at the same time, a large-scale vacuum induction furnace has been developed for key production equipment. The company's vacuum smelting technology has obtained domestic and foreign invention patents. 13 items, leading technical level.

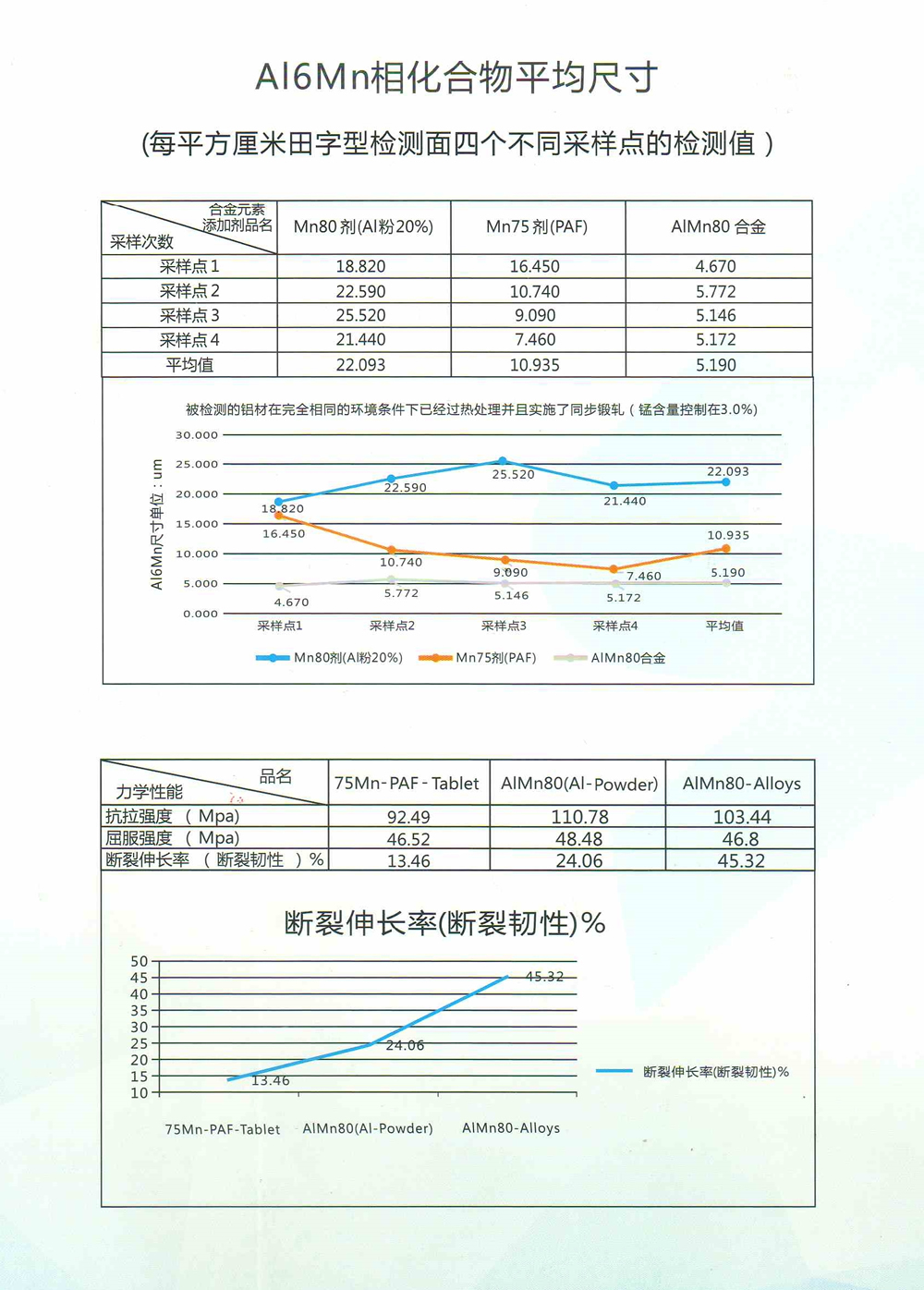

At present, the mainstream aluminum-manganese alloy element additives in the aluminum processing market are manganese flakes composed of 80% manganese powder and 20% aluminum powder. This kind of alloying element additives will cause a large amount of aluminum powder to be burnt during use, and a large amount of smoke will be generated during use to pollute the environment. In order to further improve the performance of aluminum alloy element additives and reduce the comprehensive application cost, Shenzhen Xinxing lasted 10 years and finally developed four new cemented carbide element additives (AlMn80, AlCr40, AlFe60, AlSi70) series products. This series of products completely overcome the shortcomings of traditional alloy element additives (tablets), greatly reducing the production and application costs of aluminum processing enterprises (compared with the popular selling prices of traditional products) and the impact on the application environment. The most important thing is the quality of the produced aluminum (for example, the use of aluminum-manganese 80 alloy) and its mechanical properties-the elongation at break (fracture toughness) increases exponentially. The launch of these new cemented carbide element additives will greatly promote the quality improvement of high-end aluminum materials. The new cemented carbide element additive products developed by the company can completely replace traditional alloy element additives (tablets).

Normally, the samples delivery is 1-3 days and the lead time for the official order is 3-15 days.

Yes, the samples will be free if you agree to place orders. Otherwise, we will charge the samples.

The United States, Canada, Europe, Africa, Asia and other countries and regions.

Yes, we have more than 10 years of export experience, 95% of the products exported to overseas markets. We specialize in high quality aluminum alloy Mn additive tablets, (Fe, Cu, Ti, Cr, Ni) additive tablets, quick-melt silicon and other aluminum alloy additives.